PRODUCT CENTER

PRODUCT CATEGORY

Automatic terminal machine

Product Category

Rotational speed:18 rpm

Turning method:Intermittent start, program controlled

Power supply power:6W 220VAC

Rotational speed:18 rpm

Product Description

Product Description

The PUDONG automatic double-head terminal machine PD-02ST changes the traditional cam drive technology and adopts a programmable control system with a high precision stepping system. The equipment uses a microcomputer system to control the knife cutting unit, the "computerised knife adjustment" mode is very convenient in terms of adjusting the stripping length, the operator just sets the value on the touch screen to complete, the master adjuster does not need too much technical experience, can also easily operate, easy to learn and understand, its for some of the more stretchy non-standard wire, the "computerised knife adjustment" mode is very convenient. The advantages of the "computerised knife adjustment" technology are particularly obvious. The machine's crimp positions are set digitally in front/back and left/right positions. This revolutionary technical improvement makes the operation and adjustment of the PD-02ST automatic terminal punching machine incredibly easy.

Equipment parameters

| Parameters of the automatic terminal punching machine | ||

| Paper take-up unit | Power supply power | 6W 220VAC |

| Rotational speed | 18 rpm | |

| Turning method | Intermittent start, program controlled | |

| Take-up belt device | Power supply power | 6W 220VAC |

| Rotational speed | 18 rpm | |

| Turning method | Continuous operation, mechanical control | |

| Detection device:detects the presence or absence of wire, knots in the wire | Power supply power | 60W 220VAC |

| Rotational speed | 0~435 rpm | |

| Turning method | Intermittent start, program controlled | |

| Detection devices | Detects the presence or absence of wire, kinked wire | |

| Specially developed and designed for automatic terminal machines, it can provide the host machine with the required wire at the right time and in the right quantity, so that the host machine can process wire without resistance and ensure wire processing accuracy | ||

| Can also be used with other models of automatic machines (on request) | ||

Product Features

1、Automatic terminal punching machine the most convenient operating system - cutting wire length, stripping length, cutting into the depth, terminal crimping before / after, left / right position and almost all parameters are set on the touch screen, easy to operate, save labor, reduce the time to debug the machine.

2、The fastest production speed - the length of the wire within 100mm, the fastest production per hour can be about 4500, including the wire cutting, both ends of the peeling, both ends of the terminal crimping and other actions, this is the current domestic (including Taiwan-made) similar models have the advantage of the production capacity of the model.

3、PD-02ST automatic terminal machine supporting the terminal machine is used to have FM control system of silent terminal machine, the body structure is delicate, universal OTP / 2000 type, such as horizontal, straight feeding card die are applicable, and the existing semi-automatic terminal machine tool, die adjustment method is exactly the same.

|

|

|

Keys: Ultrasonic welding machine,Stripping machine

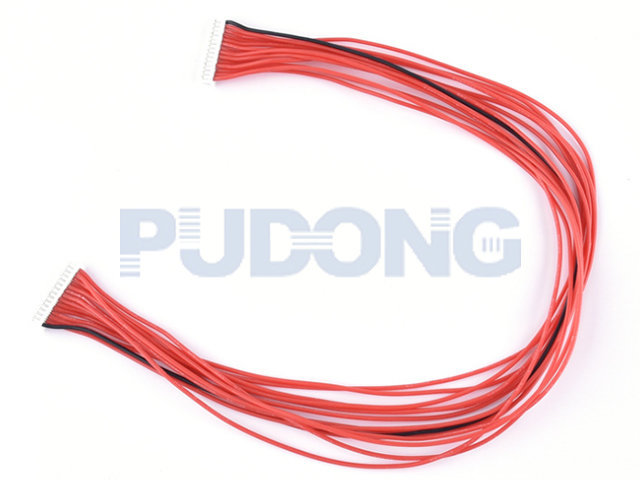

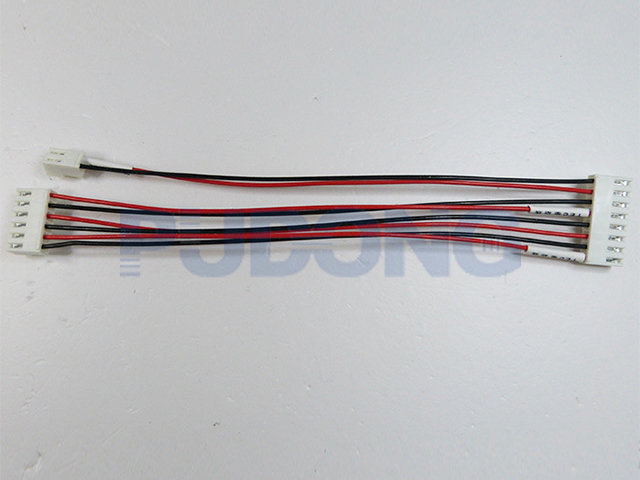

Related Products

Online Messages

Contact Information

Business Consulting:

+86-15261110017 lulu

+86-18861130806 luisa

Address: Building 36, No. 158 Jinchuang Road, Changzhou Economic Development Zone, Jiangsu Province

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans