PRODUCT CENTER

PRODUCT CATEGORY

Press terminal shell-piercing machine

Product Category

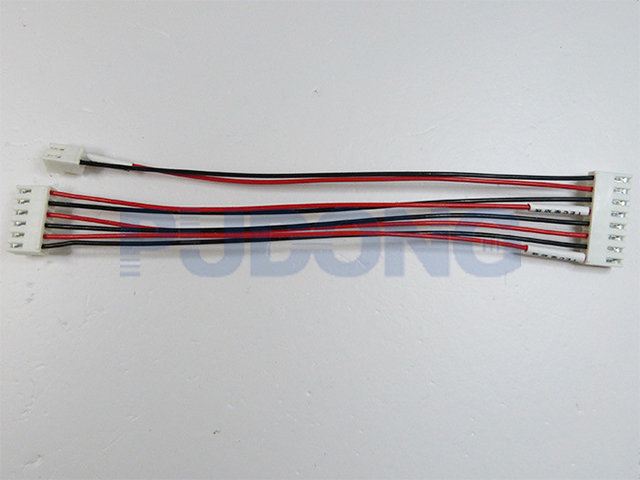

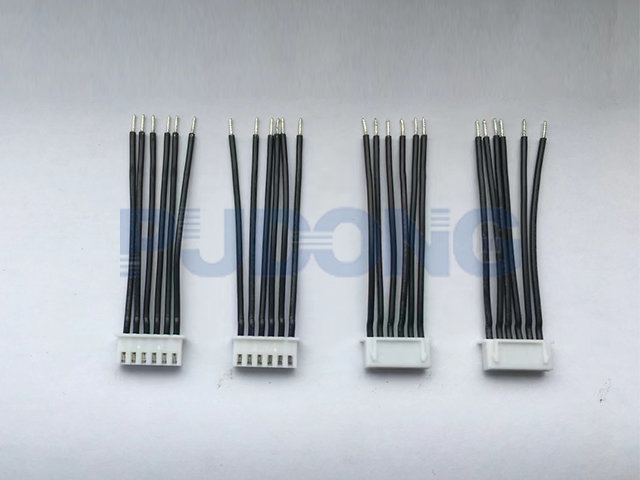

Name:Automatic Crimping and Inserting Machine

Function:1-16 wires cut, stripped, crimped, tinned and cased in one go

Wire diameter range:18#-28#Electronic wire

Cut-off length:50-500mm

Tangential accuracy:0.1mm

Stripping length:1-15mm

Product Description

Product description

The machine can process 1-16 electronic wires of different colours at the same time, completing a series of actions at once: automatic feeding of wires, fixed length cutting, automatic stripping and twisting of wires, automatic single and double head pressing of terminals, automatic tin dipping and automatic rubber shell wearing. The equipment is our main product, in order to ensure product quality and stability, the whole machine configuration are used well-known brands, full servo drive, PLC and touch screen human-machine interface as the core control system, equipped with pressure sensing system and visual inspection system to strictly control the effect of crimping terminals, through the shell effect, to reduce the generation of defective products, so that the product almost reach zero waste, the real automation operation, only need simple training The machine can be easily operated by anyone with simple training.

Equipment parameters

| Model | DZJ-CK-ZX06 | Crimp area | 2.0T cast iron ultra-quiet terminal machine |

| Name | Automatic Crimping and Inserting Machine | Applicable abrasives | OTP horizontal and straight moulds, other moulds |

| Function | 1-16 wires cut, stripped, crimped, tinned and cased in one go | Monitoring projects | Wire presence or absence, terminal presence or absence, air pressure detection, motor abnormality detection, pressure detection, shell penetration detection |

| Wire diameter range | 18#-28#Electronic wire | Compressed air | 0.5MPa |

| Cut-off length | 50-500mm | Supply voltage | AC220V 50/60Hz 20A |

| Tangential accuracy | 0.1mm | Dimensions | 1800mmX800mmX1860mm |

| Stripping length | 1-15mm | Weight | 650kg |

Product features and advantages

1、High efficiency, up to 16 electronic wires of the same or different colours can be processed at the same time.

2、The whole machine servo drive, PLC control system, to achieve stable quality, accurate value, high speed and low noise effect, digital operation: cutting length, stripping length, hitting end position, wrapping length, dip tin depth, insert shell position, twisted wire strength are digital debugging, modular design, each action can be run independently.

3、Moving parts adopt the combination of brand guide rail module, smooth movement, stable and durable, even after years of use, there is no need to worry about the gap caused by wear and tear to affect the accuracy of the product.

4、The press terminal part adopts XY axis double guide rail design to improve the accuracy of playing terminals, and the press terminal part is equipped with imported pressure management system and other testing devices, which can eliminate abnormal products in a timely manner and achieve zero scrap of products without inspection.

5、Housing conveying part: Adopt vibration plate precision direct vibration into conveying housing mode, wearing housing action with CCD visual alignment system, efficient and accurate detection of wearing housing in place.

6、Equipment parts are made of wear-resistant, high-temperature and corrosion-resistant materials, and the surface of metal materials are plated and heat-treated, which makes the machine look beautiful and not easy to wear and rust, ensuring the stability of the machine.

7、The machine is equipped with a waste disposal and recycling device, with a vacuum waste suction device under the knife frame and a blowing device to ensure a clean working environment and avoid the phenomenon of cutting copper wire due to the rubber being stuck in the knife mouth. Flux reflux structure and tin scraping device can make flux and tin recycling, saving costs for the company.

|

|

|

Keys: Ultrasonic welding machine,Stripping machine

Related Products

Online Messages

Contact Information

Business Consulting:

+86-15261110017 lulu

+86-18861130806 luisa

Address: Building 36, No. 158 Jinchuang Road, Changzhou Economic Development Zone, Jiangsu Province

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans