PRODUCT CENTER

PRODUCT CATEGORY

single-head tin impregnating equipment

Product Category

Function:Wire cutting, single end stripping, double end stripping, double end splitting, single end crimping, single end tinning

Power source:220V/50/60HZ Single Phase

Productivity:Over 24 times/minute (exact production capacity varies according to type of wire, size of wire diameter and type of terminal)

Applicable terminals:XH、PH、2510、Spring-loaded terminals, etc.

Applicable wires:Red and white rows, blue and white rows, coloured rows, grey rows, etc.

Product Description

Product description

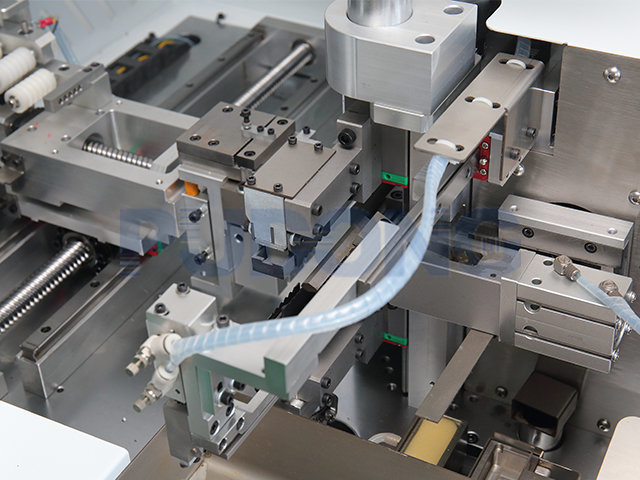

Automatic single head press terminal dipping tin machine, is for all kinds of row of wire automatically complete: cutting, peeling, splitting, single head press terminal, single head dipping tin a series of actions. The machine is controlled by an imported PLC system, easy to learn and understand. Servo motor and imported ball screw with drive, so that the wire feeding, peeling, hitting the end, dipping tin and other positions are very accurate and fast, the action between each other connected smoothly, wire feeding using wire pulling clamps to pull the wire, to avoid the inaccuracy of the wrapping, long and short wires and other phenomena. The knife holder part, the front peeling part and the back peeling part are changed from the traditional gear structure to the module design structure, avoiding the problem of the accuracy of the knife holder part due to the wear and tear between the machines after a period of time, and the depth of the cutting knife only requires the input of parameters on the screen without any manual adjustment. It is truly automatic. The knife holder part is driven by a servo motor for precision and accuracy.

The PD-06DT-PX PLC is programmed and controlled, all actions can be operated by touch screen, easy to operate. Data adjustment can change the stripping and cutting length, cutting depth, hitting end position, tin dipping time, etc., saving time for the adjuster.

Equipment parameters

| Model | PD-05DT-PX |

| Function | Wire cutting, single end stripping, double end stripping, double end splitting, single end crimping, single end tinning |

| Power source | 220V/50/60HZ Single Phase |

| Productivity | Over 24 times/minute (exact production capacity varies according to type of wire, size of wire diameter and type of terminal) |

| Applicable terminals | XH、PH、2510、Spring-loaded terminals, etc. |

| Applicable wires | Red and white rows, blue and white rows, coloured rows, grey rows, etc. |

| Cut-off length | 25mm-600mm (Special lengths can be made to order, minimum cut-off lengths vary according to stripping size and shape of crimped terminals) |

| Wire diameter range | 2-12pin (18-30 gauge) wire |

| Tin dip depth | 0.2mm -10mm |

| Pressing power | 1.5 - 2 tonnes |

| Air pressure | 5 - 6 kgf (Clean and dry air required) |

| Detection devices | Low air pressure, abnormal motors, low temperature alarms, abnormal crimp terminals, etc. |

| Body dimensions | 650mm×850mm×1300mm |

| Weight of fuselage | 400kg |

Machine features

1、The machine is controlled by imported PLC system, touch screen operation is easy to learn and understand. Professional engineers to write software, splitting, cutting wire, stripping, dipping tin and other actions related to the time action will automatically with the adjustment;

2、The production range of wire can be from AWG18 ---AWG30 Teflon, silicone PVC, double parallel wire, row of wire, etc., with a wide range of practicality;

3、This machine is close to 90 degrees dip angle, so that the wire diameter dip tin degree average (dip depth accurate) and dip tin time dip tin depth can be set by themselves, more convenient for workers on different specifications of wire processing, and at the same time can achieve half dip tin effect;

4、The scrap disposal device is installed at the cutting and stripping position to avoid cutting off the copper wire due to the scrap not falling off in time, and the tin furnace is designed with an automatic scraping device to make the surface of the tin dip free of oxidized tin chips and to ensure the neatness of the table.

|

|

|

Keys: Ultrasonic welding machine,Stripping machine

Related Products

Online Messages

Contact Information

Business Consulting:

+86-15261110017 lulu

+86-18861130806 luisa

Address: Building 36, No. 158 Jinchuang Road, Changzhou Economic Development Zone, Jiangsu Province

Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans